Now, the U.S. chip industry registers another monumental achievement with the recent launch of silicon wafer production at America-based GlobalWafers. With investments from Apple and TSMC, this is a watershed moment for the chip independence of America.

GlobalWafers Boosts U.S. Chip Industry

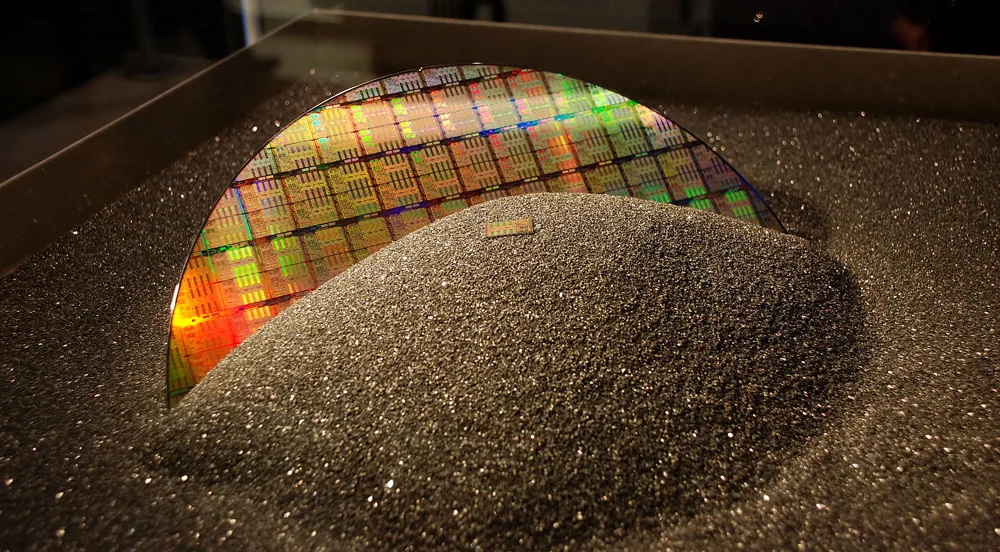

Until several years ago, silicon wafers used in the United States were sourced almost entirely from overseas suppliers, chiefly from Japanese companies including Shin-Etsu Chemical and Sumco. Now, with silicon wafers here in America, we will finally have a supply chain to produce the most advanced chips in the world faster, cheaper, and more secure than ever before.

Taiwan Economic Daily said that GlobalWafers was setting up a large-size production facility in Texas. This expansion enables the company to produce silicon wafers in the U.S. and serve semiconductor giants such as TSMC, and other chip makers a local, steady supply.

Importance of Silicon Wafers in the USA

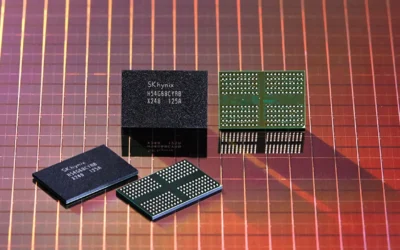

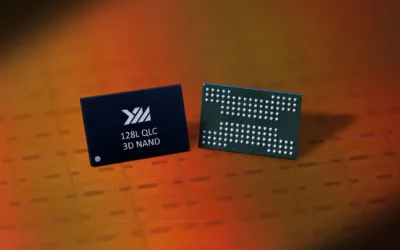

Silicon wafers sit at the bottom of the chipmaking process. Companies such as TSMC depend on 300mm (12-inch) silicon wafers to build advanced processors. Chip production cannot even start without wafers.

GlobalWafers silicon wafers find their way into U.S. chip factories that won’t be postponed anymore due to imports. Its first phase will have a capacity of 300,000 wafers per month, powering up America’s semiconductor ecosystem chain directly.

Texas Set to Become the Next Epicenter for Silicon Wafers

Mark England, GlobalWafers senior vice president of marketing and sales, noted Texas provides “the ideal location” because of tax incentives, logistics and the state’s semiconductor ecosystem. Silicon wafers inside the U.S. will make the state a foundation of American semiconductor development.

The transfer is consistent with U. S. government policy that regards semiconductors as a national security issue. With TSMC and Samsung pouring capital into American semiconductor plants, GlobalWafers’ Texas expansion is a milestone in a next-generation American silicon wafer production era.

Semiconductor industry: From East to West pivot

Arch-rivals are reorienting the traditional playing field of semiconductors. The U.S. is peeling off the Asian silk layers of silicon wafer suppliers by localizing silicon wafer production on U.S. soil, allowing for a move towards greater technological self-reliance.

Not only does the development bolster America s chip industry, it also should provide TSMC and other billion dollar investors in U any chipmaking plants with easier supply.

FAQs

Silicon wafers are the basic building blocks in the chip manufacturing. This means if we grow the silicon wafers right here in America, be it faster, more organization and simply cheaper to produce in the end without having to rely on importation.

Local supply of silicon wafers helps major chipmakers such as TSMC, Samsung and U.S.-headquartered semiconductor firms in America

The facility in Texas will have a U.S. production capacity of 300K silicon wafers monthly when fully operational.

With state tax incentives for companies, strengthened supply chain, and the growing number of semiconductor investments, Texas has emerged as one of the most potential centers of silicon wafers in America.